Crowd-funding a high-NA multi-immersion objective lens

We have designed a promising high-NA multi-immersion all-immersion objective lens that has applications for both cleared tissue imaging and live-cell imaging. We would love to make this objective generally available, but we need the help of the research community.

The initial design was completed just prior to the COVID pandemic and there are interested researchers, but we are stuck in a chicken-and-egg situation 1.5 years later. For custom optics like this there are large fixed costs for both design and manufacturing, so to get a reasonable per-unit price you need to make a lot of them. But making a lot of them is a large investment that could be a loss if they don’t sell.

We were recently in a similar situation with the “King Snout” objective lens, but enough scientists placed pre-orders that ASI was comfortable proceeding with a production run. We’d like to replicate the same model with this all-immersion objective lens. Consider it a crowdfunding appeal; ASI is willing to bear significant financial risk, but only if there are enough customers who agree to purchase the resulting product.

So here’s the offer: ASI will proceed with a production run if we receive POs for seven of these objectives by end-July 2021, with expected delivery in November 2021. We will offer a special price of $25k for any orders received by July 31. Update: We did not meet our goal of getting commitments for 7 of these, however the interested leading scientists are still interested so we are keeping a lookout for anyone else who would be willing to pre-order these.Leading scientists have already promised to purchase 3 of them, so we need another 4 customers to get us over the hump. Any production run will be for at least 15 objectives, so there will be some left for future orders. But the scientists who pre-order will not only be the first to get their hands on them, but will also further the entire field by helping to make this objective lens a reality.

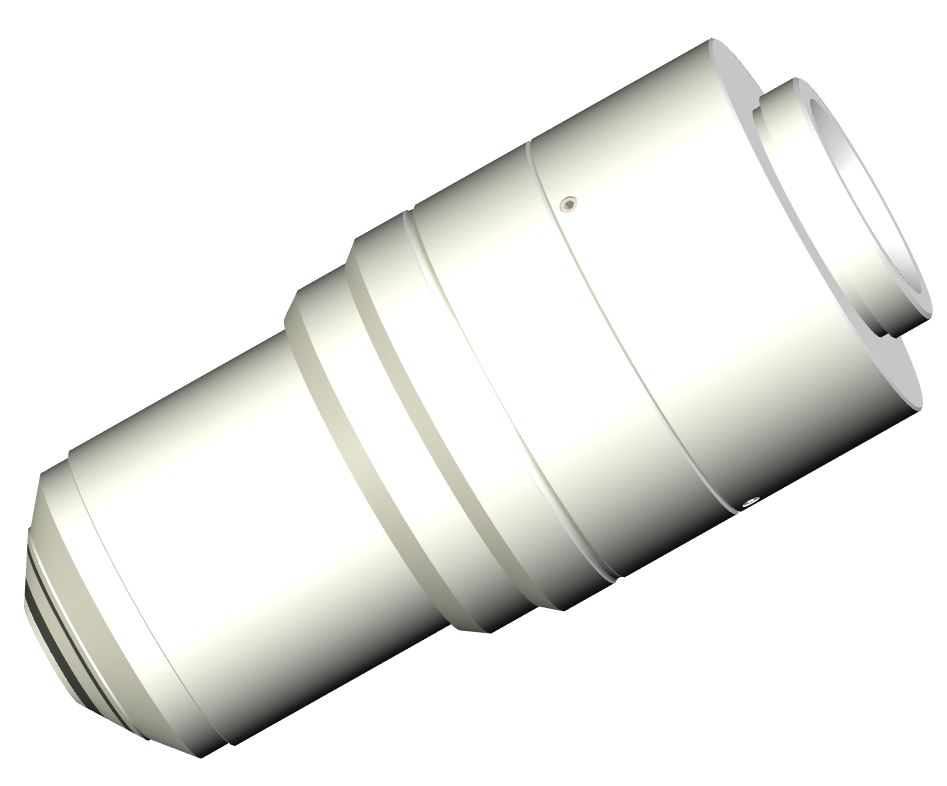

We are happy to share CAD and Zemax black box models. Please contact me at jon@asiimaging.com for more information or to request a formal quote.

Here are the main specifications:

- Magnification / NA in BABB : “56x” / NA 1.24

- Magnification / NA in CLARITY: “52x” / NA 1.15

- Magnification / NA in water: “48x” / NA 1.05

- Working distance: 3.4 mm

- Optical / mechanical angle: 52° / 57°

- Field of view: 0.5 mm

- AR coatings: 400 – 1300 nm

- Plan-corrected, apochromatic, optimized for visible

- 83 mm parfocal distance, M25x0.75 threads

What will this objective be good for? I’m glad you asked! There are at least 3 categories of applications:

-

- Cleared tissue imaging

- Single-objective light sheet

- High-NA light sheet (e.g. lattice light sheet)

Obviously this objective lens will be an excellent choice for any application involving high-resolution cleared tissue imaging. It will have the highest NA — and hence best resolution — of any objective for imaging cleared tissue. It can be used in any of the various media for cleared tissue, spanning the refractive index (RI) range from water to BABB or ethyl cinnamate. Like our other multi-immersion objectives it features a curved first surface which allows it to be used in any dipping medium without a correction collar. We expect it to be resistant to harsh organic chemicals like DBE and BABB like our other multi-immersion objectives.

Single-objective light sheet and remote refocus rely on creating a remote 3D image of the sample through a carefully-constructed optical relay, which requires adjusting the system magnification to match the sample. This magnification change happens automatically if an all-immersion objective is used as the primary objective. Hence this objective presents the opportunity to construct a versatile single-objective microscope system that can be used for various media, as well as having exceptional working distance and 52° optical angle. Even though it is a dipping objective, it is possible to use a coverslip at the sample and correct for it at the remote image (by using a coverslip-corrected objective without a coverslip for O2).

Finally, this objective lens will be useful for any sort of high-NA live imaging including lattice light sheet. The original Nikon 25x/1.1 W lens used for lattice light sheet has many disadvantages, but it has excellent “mechanical efficiency” or large NA for the amount of room it takes up near the sample. Our new objective fits into the same space near the sample as the Nikon 25x/1.1 W, but it has significantly more working distance (3.4 vs. 2.0 mm), is 8 mm longer (83 vs. 75 mm parfocal distance), has magnification more suited to high-resolution imaging, and a flat field. The penalty is a slightly reduced numerical aperture, NA 1.05 in water instead of NA 1.1 (5% worse lateral resolution and 11% worse axial resolution). An under-appreciated fact is that the exact working distance (WD) of most dipping/immersion objectives changes as the exact RI of the medium changes — including as the temperature changes — owing to refraction at the objective/medium interface. Thus long-term light sheet imaging usually requires continual adjustment of either the objective or light sheet position. However, all three of ASI’s multi-immersion objectives has the exact same WD regardless of medium RI, simplifying experiments.

Here are some links for those interested in digging deeper:

- slides for MBL LSFM presentation 10-May-2021

- details on all of ASI’s multi-immersion objectives including this one