Selective Plane Illumination Microscopy

SPIM or LSFM Overview

What is SPIM or LSFM?

Selective Plane Illumination Microscopy (SPIM) is fast and gentle imaging technique that combines the speed of widefield imaging with moderate optical sectioning and low photobleaching. It has become an important fluorescence imaging modality, especially for volumetric imaging. SPIM is also referred to as Light Sheet Fluorescence Microscopy (LSFM) or simply “light sheet”.1

The defining feature of SPIM or LSFM is planar illumination of the focal plane from the side. Only a thin section of the sample is illuminated at any given time, minimizing photodamage and also providing optical sectioning which improves SNR compared with widefield epi-fluorescence. Because the image is collected in a widefield (2D parallel) manner, light sheet imaging is much faster than a point-scanned confocal microscope which detects only one pixel at a time.

“Comparison of Different Microscopy Illumination Modalities (LSFM: Lightsheet Fluorescence Microscopy, WF: Widefield Microscopy, CF: Confocal Microscopy.” by JKrieger used under CC BY-SA 3.0, Wikimedia Commons, June 7th, 2013.

Light sheet microscopy has rapidly gained popularity for volumetric imaging because of three key features: First, photodamage is minimized because of excitation is confined near the focal plane, e.g. living things stay alive for much longer. Second, good optical sectioning is obtained, often approaching that of confocal microscopy. Third, acquisition rates are very fast, orders of magnitude faster than a traditional confocal microscope.

The main disadvantage of SPIM is that extra optics are required to generate the light sheet. Most commonly a separate illumination objective lens is placed orthogonally to the detection objective and sheet-generating optics are placed between this illumination objective and the laser source. Adding the extra lens introduces steric constraints to both the imaging system and sample mounting. In essence, the microscope needs to be designed around the sample, so there are a wide variety of light sheet microscope designs each optimal for different samples and different mounting requirements. In contrast, traditional confocal or epi-fluorescent microscopes have a single optical path and can accommodate a much wider variety of samples. In other words, the advantages of SPIM come at the cost of more narrow applicability of any single instrument; this has led to the explosion of different light sheet microscope configurations, each with their own advantages and disadvantages.

1Some reserve the term “SPIM” for static light sheet generated by a cylindrical lens in contrast to scanning a beam to generate the light sheet. Others, including ASI, use SPIM as equivalent to LSFM, in part because it’s possible to easily change the type of light sheet generator and otherwise keep the identical microscope configuration.

How can ASI help?

Applied Scientific Instrumentation (ASI) has been taking a modular approach to constructing microscopes for over a decade, and since the early 2010s we have added components to our offerings specific to light sheet microscopy. ASI’s modular components can be easily combined to make a complete SPIM microscope including motorized and piezo stages, optomechanics, and scanners for creating and moving the light sheet. Objective lenses, lasers, filters, and cameras are required to complete the system; users can procure these other items themselves from the respective manufacturers, use the services of various system integrators reselling ASI hardware, or purchase them via ASI.

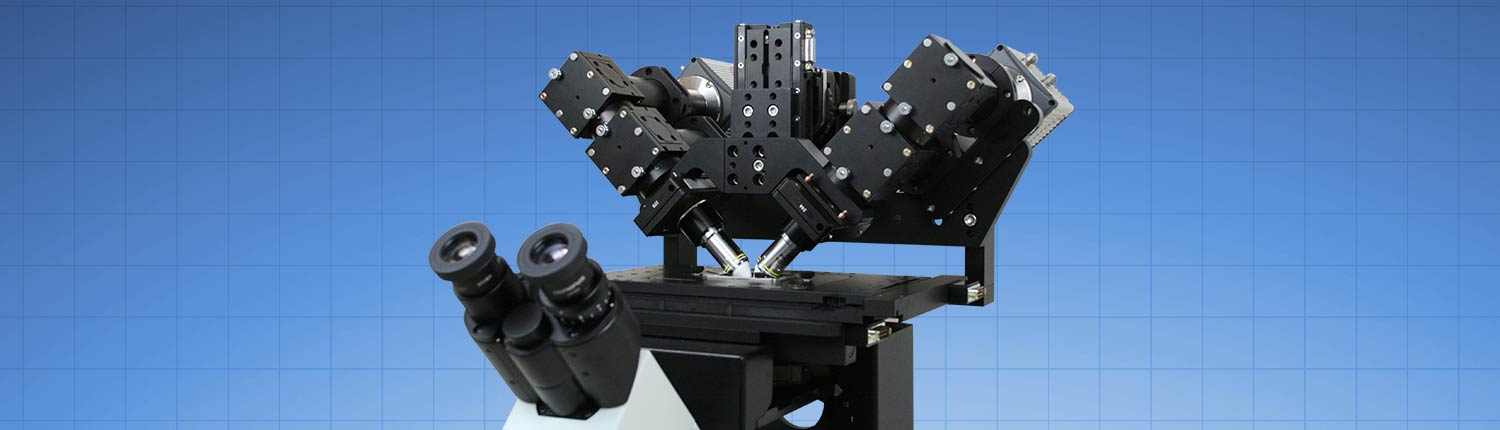

ASI offers light sheet microscopes in several standard configurations including iSPIM, diSPIM, oSPIM, and ct-dSPIM. Furthermore, using ASI’s components greatly simplifies building custom/DIY light sheet systems.

Perhaps the most difficult aspect of implementing a light sheet microscope is synchronizing the various components including sample movement, cameras, lasers, and moving a beam to create the light sheet. These sub-millisecond timing events are handled by ASI’s controller according to the settings previously sent over serial commands. Furthermore, ASI has contributed to a free and open source Micro-Manager plugin which makes it easy to configure the relevant controller settings and acquire SPIM datasets.

Generating the Light Sheet

There are two main approaches to generating a sheet of light. A cylindrical lens or similar element can be used to focus light in one axis (the sheet thickness) while leaving it spread in the other axis (the sheet width), thus illuminating the entire field of view all at once. This is commonly referred to as a “static” sheet. The other method is to use a galvo mirror to scan a beam of light across the field during each exposure of the imaging camera, sometimes called a “digital” or “scanned” sheet. Each approach has advantages and disadvantages. Static sheets spread the excitation dose out in time which can reduce photodamage and are less complex to generate. However, illumination intensity usually isn’t constant over the field owing to source’s origin as a Gaussian beam. Digital sheets are uniform over an easily-changed width, have a “stop motion” effect which is beneficial for moving samples, and can be combined with a camera’s rolling shutter for 1D confocality. Due to sCMOS camera readout, static sheets can usually attain higher frame rates. But the rolling shutter can allow multiple light sheets to be created simultaneously in multi-view schemes.

The ideal light sheet would be extremely thin, with intensity completely confined to the focal plane of the detection objective, and long enough to cover the entire field of view of the imaging optics. But physics intervenes. Focused light diverges, so the thinner the sheet the shorter the thin region. The distance over which the sheet is relatively thin is called the confocal length and generally scales quadratically with sheet thickness. In practice the confocal length is generally matched to the size of the sample or field of view.

Most often sheet has an approximately Gaussian profile because the laser source originates as a Gaussian beam. For the case of a static sheet this Gaussian profile is in the focused direction, mathematically the same as sweeping a Gaussian beam. The thickness and confocal length of a Gaussian beam/sheet can be derived analytically as:

waist thickness = k1 * λ / NAill

confocal length = k2 * λ / (NAill)2

where k1 and k2 are dimensionless constants and depend on the chosen definitions of thickness and confocal length, λ is the vacuum wavelength, and NAill is the numerical aperture of the illumination beam. For common definitions k1=k2=0.64. The illumination NA can be no larger than the NA of the illumination optics but most often is only a small fraction of it so that the confocal length is sufficiently large as previously explained.

Non-Gaussian beams have been employed to generate light sheets including Bessel, Airy, and arrays of Bessel beams. Bessel and Airy beams have the desirably property of being non-diffracting or self-healing which reduces shadowing. Bessel beams are much thinner relative to the confocal distance than Gaussian but include a large significant amount of excitation light outside the central thin lobe, increasing photodamage. Arrays of Bessel beams can be used where the array spacing minimizes the out of focus light via destructive interference (a “lattice”) which can have excellent efficiency but requires very complex sheet generating optics and is very sensitive to sample scattering and aberrations. Interference can be used to reduce sheet thickness in simpler schemes as well. The fundamental tradeoff between confocal length and thinness remains for such non-Gaussian beams, just with a different scale factor.

Opaque regions in the sample can block the light sheet leading to stripe artifacts which are shadows where illumination light never reaches. This can be mitigated by pivoting the light sheet using a galvo conjugate to the imaging plane and is called anti-striping.

To collect 3D or volumetric information either the light sheet needs to be moved through the sample or else the sample moved through the light sheet to create a stack of images. The light sheet can be moved using a galvo mirror, and the focal plane of detection objective needs to be moved in tandem (usually with a piezo stage). Alternatively, the sample can be moved through a spatially stationary light sheet using either a motorized or piezo stage. Although the during-stack acquisition speed is limited mainly by the camera speed and sample brightness, piezo stages are preferred for fast volumetric imaging because they can fly back to the initial position faster than motorized stages. Motorized stages are preferred for large and/or flat samples.

Optical Resolution

As previously mentioned, Bessel beams and lattices can achieve very thin light sheets at the expense of extra complexity. Bessel and similar beams suffer from large amounts of out of focus light but can be useful for multi-photon and samples where overcoming shadow artifacts is more important than excess photodamage. Lattices are very sensitive to sample-induced aberrations but can be useful for small samples.

Lateral (XY) resolution is the same as widefield microscopy and is inversely proportional to the detection NA. Lateral resolution is usually much better than axial resolution, the same as other microscopy modalities.

Axial (Z) resolution is more complicated. The baseline axial resolution is the depth of field of the detection objective, which is inversely proportional to the square of the detection NA. However, the axial resolution can be improved if the light sheet is thinner than the depth of field. The effective axial resolution is the convolution of the excitation and detection PSFs (the illumination PSF actually varies slightly due to sheet divergence but can be approximated as the beam waist).

If the detection NA is low (e.g. 0.2) the depth of field is so large that it’s usually possible to generate a light sheet thin enough to improve axial resolution. However, even so axial resolution will generally remain poor compared to lateral resolution.

For high NA detection objectives (e.g. NA 0.5 and above) the depth of field is a few microns and it is difficult to generate sheets thinner than this over a practically-large field of view. In this situation, the light sheet is somewhat thicker than the depth of field and so axial resolution is the same as widefield imaging and optical sectioning is helpful but imperfect. Thus deconvolution of the resulting data can improve image quality by reassigning out of focus light to the source.

If smaller field of view is acquired and “tiled” across the sample, then a thinner sheet can be used to improve axial resolution. However, this increases the photon dose and possibly the acquisition time. Conceptually these “tiling” or “axial scanned” schemes become increasingly confocal as the field of view gets smaller, resulting low photon efficiency and increased photobleaching compared with SPIM with a large field of view.

If the sample is imaged from different vantage points then these individual 3D datasets can be combined into a single 3D dataset with improved resolution. For example, in the diSPIM two orthogonal views of the same sample are collected, each view having good lateral resolution and poor axial resolution. However, each axial direction corresponds to a lateral direction in the other view. After registration and joint deconvolution a single dataset with isotropic “lateral”, resolution can be generated. The same approach is commonly applied to samples that are rotated between collection of images from different views. Data post-processing often requires much more time and effort than the acquisition, but only need be done on known-good datasets (by viewing the aniotropic individual stacks). Furthermore, registration between multiple views requires that the sample be significantly identical between them, i.e. it cannot have significantly moved or deformed.

Configurations

ASI offers a variety of modular microscope elements to easily implement light sheet microscopes including:

- Motorized and piezo stages

- Light sheet generators for either static or scanned sheets

- Tunable lens for remote focus and translating beam waist

- All associated control electronics, including coordination of these elements with cameras and lasers

- Optomechanics, e.g. filter holders, kinematic mirrors, tube lenses

- Objective for cleared tissue imaging

- Other modules generally useful for infinity microscopes including hardware autofocus, LED illuminators, turrets and objective changers, automated and manual filter sliders, automated and manual port switchers, filter wheels, etc.

The most common configurations of ASI hardware in light sheet microscopes are:

Others configurations:

- Zebrafish imaging

- OpenSPIM geometry with XYZΘ stage

- Open-top